Share

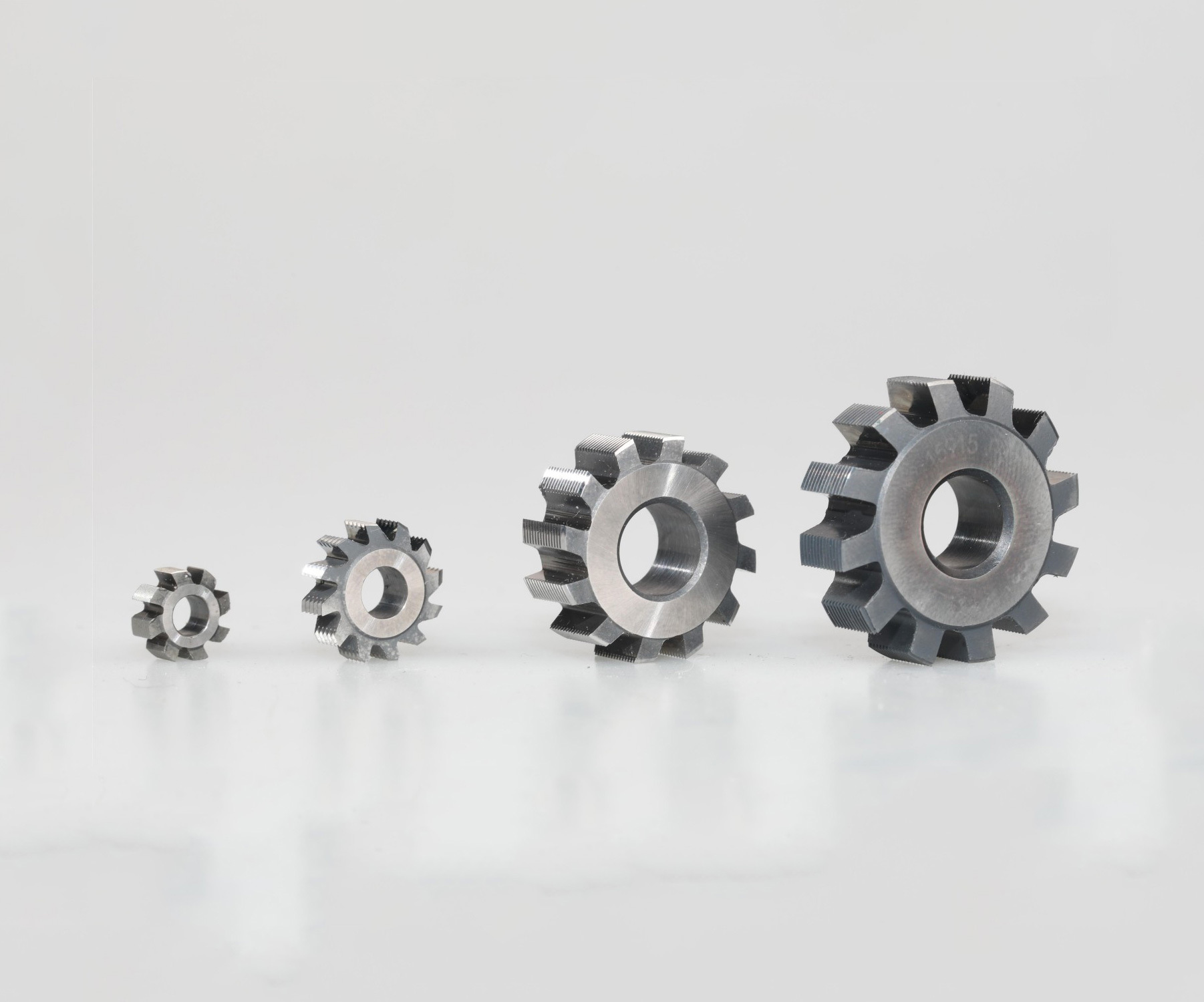

Small modulus hobbing cutter

Product model:

Still thinking about it? If you want to get a sample first,Please contact us!

Current Product Classification

Keywords

- Product Description

-

Introduction

The small module hobbing cutter is a tool used for machining small module gears. Modulus is a parameter that indicates the size of the gear tooth profile. Small modulus usually refers to gears with modulus less than or equal to 1mm. The small module hobbing cutter can process the precise involute tooth profile on the gear blank according to the principle of the spreading method.

Structure composition

Knife body part: This is the main body of the hobbing cutter, which is generally made of high-quality alloy steel, such as high-speed steel. It has enough strength and rigidity to withstand the cutting force in the hobbing process. The tool body is usually cylindrical in shape and has chip grooves on its surface for accommodating chips.

Cutting edge part: The cutting edge is distributed on the circumferential surface of the cutter body, which is a key part of the hobbing cutter. The shape of the cutting edge is precisely ground according to the theoretical shape of the involute tooth profile. The cutting edge of the small modulus hobbing cutter is generally finer, because the modulus to be processed is smaller and the precision is higher. When sharpening, it is necessary to ensure the accuracy of geometric parameters such as the rake angle and the back angle of the cutting edge to ensure good cutting performance and machining accuracy.

Working principle

In the process of gear hobbing, the gear hobbing cutter and the gear blank to be processed rotate according to a certain transmission ratio. The rotation of the hobbing cutter is like a worm with a cutting edge, and its cutting edge gradually envelops the gear tooth profile on the gear blank. Through the continuous rotation of the hobbing cutter and the corresponding rotation and axial feed motion of the gear blank, a complete gear tooth profile can be machined. The machining accuracy mainly depends on the accuracy of the hobbing cutter, the accuracy of the machine tool and the reasonable choice of the processing parameters.

Application areas

precision instrumentation industry: Widely used in the manufacture of small instrument gears. For example, the gear module in the watch is small, the accuracy requirements are extremely high, the small module hobbing cutter can meet its high-precision processing requirements, to ensure the smooth operation of the watch gear and accurate transmission ratio.

Aerospace field: There are many small transmission parts in aerospace equipment, and the gear module is small. The small module hobbing cutter can be used to process these high-precision aerospace gears to ensure the reliable operation of the equipment under complex working conditions, such as some small gear transmission mechanisms in the aircraft's navigation system and flight control system.

Medical Device Industry: Like some small medical equipment, such as dental equipment, small diagnostic equipment and other internal transmission gears, small modulus hobbing knife is required for processing to ensure its accuracy and reliability, and to provide protection for the normal work of medical equipment.

Online consultation

If you are interested in our products, please leave your email, we will contact you as soon as possible, thank you!

Related Products