Share

Liquid rocket engine thrust chamber nozzle

Product model:

Still thinking about it? If you want to get a sample first,Please contact us!

Current Product Classification

Keywords

- Product Description

-

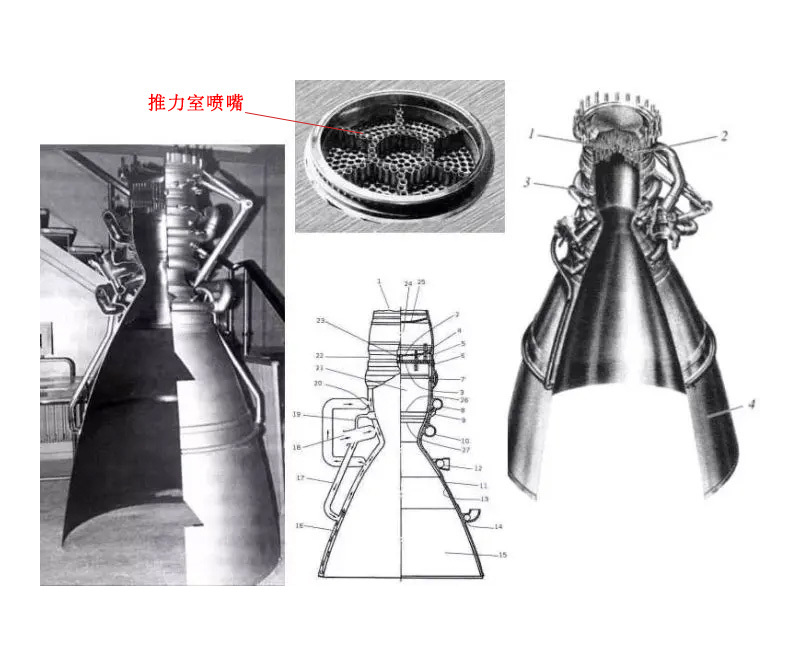

Definition and basic functions

The liquid rocket engine thrust chamber nozzle is the key component of the liquid rocket engine thrust chamber. Its main function is to eject propellant (usually fuel and oxidizer) at high speed, thereby generating a reaction force to push the rocket forward. The pressure energy and chemical energy of the propellant are efficiently converted into the kinetic energy of the high-speed jet through the nozzle.

Structural features

Convergent-divergent (Laval nozzle): This is the most common type of nozzle used in liquid rocket engines. Its structure includes a converging segment and an expanding segment. The function of the convergence section is to accelerate the propellant and partially convert its pressure energy into kinetic energy, so that the fluid velocity increases and the pressure decreases. When the fluid passes through the throat (the junction of the convergent section and the divergent section, where the fluid velocity reaches sonic velocity), it enters the divergent section. In the expansion section, the fluid continues to accelerate, and the remaining pressure energy is further converted into kinetic energy, so that the fluid speed at the outlet reaches supersonic speed, thereby generating huge thrust. For example, in the liquid rocket engines of some large launch vehicles, such as the Raptor engine of SpaceX, this type of nozzle is used, which can effectively improve the specific impulse and thrust performance of the engine.

hole shape and arrangement: Some nozzle holes are designed to be circular, and the arrangement can be single or multiple rows. In some engines that require special thrust direction control or require high combustion stability, the shape of the nozzle hole may be designed to be non-circular, such as elliptical or special polygonal. The arrangement of the nozzle holes will also be optimized according to the combustion mode and performance requirements of the engine, such as the use of concentric ring arrangements to achieve better atomization and mixing of the propellant.

Working principle

The liquid propellant is delivered to the thrust chamber nozzle through a piping system. Inside the nozzle, due to its special geometry, the pressure and velocity of the propellant change. From the point of view of energy conversion, in the convergence section, as the cross-sectional area of the channel gradually decreases, according to the fluid continuity equation (mass flow rate = fluid density × flow velocity × cross-sectional area), the fluid velocity increases and the pressure decreases. When reaching the throat, the fluid velocity reaches the local sonic speed. Then in the expansion section, according to Bernoulli's equation (static pressure = total pressure), the hydrostatic pressure is further reduced, the dynamic pressure is increased, the flow rate is further increased, and finally the rocket is ejected at high speed, generating a reaction force to push the rocket.

At the same time, the injection process of propellant in the nozzle is also accompanied by a combustion process (for liquid rocket engines that need to burn in the nozzle). Good nozzle design can make the fuel and oxidant fully mixed combustion, improve combustion efficiency. For example, in some engines that use liquid hydrogen and liquid oxygen as propellants, the internal structure and nozzle hole parameters of the nozzle are precisely designed to ensure that the hydrogen and oxygen can be evenly mixed and completely burned during the high-speed injection process, releasing a large amount of heat Energy is converted into kinetic energy of the fluid.

Material requirements

Because the liquid rocket engine thrust chamber nozzle to withstand high temperature, high pressure and high-speed gas erosion, so the material requirements are extremely high. Generally need to use high temperature, high strength materials. For example, some high performance nozzles employ nickel-based alloys or rhenium alloys. Rhenium alloys have excellent high-temperature strength and creep resistance, and can maintain structural integrity at temperatures up to 2000°C and withstand high-speed erosion by combustion products. In addition, the material also needs to have good oxidation resistance to prevent rapid corrosion in a high temperature oxidation environment, affecting the performance and service life of the nozzle.

Performance Influencing Factors

Nozzle geometry: As mentioned earlier, the geometric parameters such as the convergence-expansion ratio of the nozzle directly affect the injection speed and pressure conversion efficiency of the propellant. Different geometries are suitable for different propellant combinations and engine operating conditions. For example, for an engine that requires a high specific impulse, a nozzle with a large expansion ratio may be used, but this may also cause problems such as increased engine volume and weight.

Propellant characteristics: The type of propellant, flow rate, injection pressure and other characteristics will also have an important impact on the performance of the nozzle. Different propellants have different physical and chemical properties, such as density, viscosity, burning speed, etc. These characteristics determine the propellant flow behavior and combustion process in the nozzle. For example, higher viscosity propellants may require greater spray pressures to achieve the desired flow rate and atomization within the nozzle.

Combustion stability: The design of the nozzle needs to consider the stability of the combustion. If the combustion process is unstable, it may cause thrust fluctuations, reduced efficiency and even engine failure. The combustion stability can be improved by reasonably designing the nozzle hole size, arrangement and internal structure. For example, local overheating or uneven combustion can be avoided with a suitable orifice distribution.

Online consultation

If you are interested in our products, please leave your email, we will contact you as soon as possible, thank you!

Related Products